In the current climate of rising farm input costs, the focus must be turned towards increasing efficiencies inside the farm gate – which includes improving the quality of our core home-grown feed, grass silage. Silage quality and profitability of the farming enterprise have long been assessed side by side, with the current climate emphasising this even more for the upcoming silage making season.

Below we outline our 4 key concepts for best practise silage making this season:

1. Cutting date

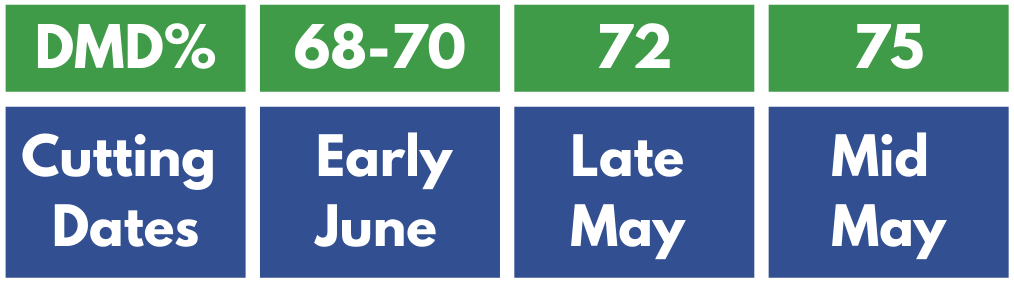

At one point, every farm will have 80% DMD (dry matter digestibility) grass available to them in the field, however, the decision is often made too late regarding the cutting date,

resulting in poor quality silage. Cutting grass younger improves digestibility and protein content, resulting in a reduced requirement for high-cost supplementation.

When discussing earlier cutting dates, silage quantity is often raised as an issue. However, it’s important to remember cutting earlier allows for quicker and earlier regrowth’s, leading to increased annual yield/ha. In some circumstances (e.g., silage only land blocks), earlier cutting will also facilitate a third cut in late August, further boosting total annual silage production.

Once seed heads appear, DMD will be around 70% at most, and will drop by 1% DMD every 2-3 days thereafter. The advice to improve average quality is to cut from mid-May. Some flexibility in harvest date (4-5 days) is usually necessary to ensure favourable cutting conditions.

2. Adapting to changes in weather

Weather is the main variable on Irish farms when it comes to silage making. Unexpected changes in weather can and will delay harvesting, however when the window of opportunity arises, seize the ‘first-cut option’. Unfortunately, last year, where the decision was made to wait – the weather broke, and many farms were forced to delay harvesting for two weeks.

Optimum mowing time is late afternoon/evening when sugars are highest (following several hours of sunshine). Sugar is the fuel for fast and efficient fermentation.

3. Effective wilting

Once cut, grass should be tethered out immediately and allowed, in ideal conditions, no more than 24 hours in the field to achieve an effective wilt. We are aiming for a dry matter content of approximately 25%. Where wilting continues for long periods, grass quality is starting to deteriorate, and significant energy losses are seen.

Over the last number of years, we have become over-reliant on long periods of wilting, and in many cases over-wilting, leading to dry silage and unstable pit-faces. Dry silage is prone to secondary fermentation, heating and energy losses.

4. Using a silage additive

With the value that is now placed on home-grown forage, achieving a good fermentation to preserve it is more critical than ever. The use of an additive has long been proven to improve fermentation, leading to less waste. Aside from less dry matter losses, the main aim of using an additive is to retain as much nutritional value as possible from the field to the pit. Silage treated with an additive has been proven to achieve a better feed-out, with increased dry matter intakes, added energy content and increased digestibility, resulting in improved animal performance.

Our GrasZyme SugarBoost is proven to:

• Increase ADG by 110 g/head/day in beef situations

• Increase milk production from forage by 1 litre/cow/day

• Increase DM intakes by 0.4 kg/head/day

• Increase milk protein percentages by 0.09%

• Reduce fermentation losses by 6.1% (equates to 30t in

a 500t pit)

Need help or advice?

For a tailored plan on improving forage quality on your farm, contact your local Sales Advisor.